Education - Forum for Technicians and Engineers.Quick Navigation Commercial CNC Wood Routers Top but its inconvenience is that we have to run with win98. We are doing all of this right now and a hell of allot more. This is just a part of what this software as to do.I haven't talk about all the fine parametric tuning of STD models.

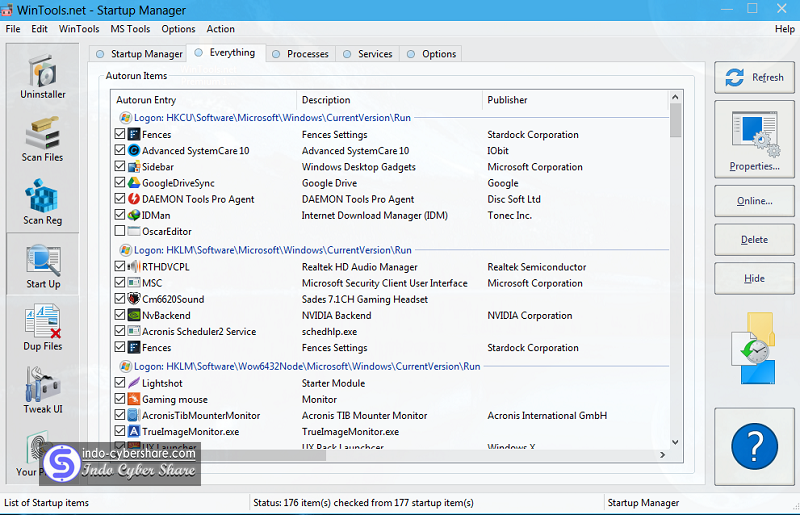

Once this is done the generator places his tools in the specific location in the software and the software generates and sends g-godes to the controllers. this software has to grab theses info from the scans and nest them into 5X9 MDF sheets with what ever spacing we ask between them. Then A so called "generator" (employee) scans them in the computer. Once it's done the client orders is doors and drawers for all of his kitchen. The software has to work so i only have to make one program of this interior shape that wil adapt to anny dimensions. I make the main program either like we do now or with cad aid. So lets say a client wants a specific interior shape for his doors or drawers. We make thermos MDF cabinet doors and drawers. I appreciate any new help and info on if there's a software for us. We looked it out with MasterCam and SolidWorks software programmers at a CNC show but didn't seem to be able to completely suite us.Īnd then i heard a bit about AlphaCam that seem to maybe have what we are looking for. Now i know some of you will say that wintools can be compatible with higher than win98. txt file (model program) and generate it to send to the cnc. Making one program for all is letting us work with a system that is almost 100% automated.Īnother point in this is that we only have to scan the order's bar code and the system automatically pickup's up the width length height and model and the amout of parts of the order.Then the generator's job is to simply place his tools in the rite spots for wintools to read our. This way of parametric programming lets us use only one model program to machine the interior of any different width length and height of a part. txt file that the software creates when you acualy draw and add your tool path to that first line. This means that we program and apply tool path's before and without even touching the "create line" in the cad/cam software. We program with the actual language of CMSwintools no g-codes no CAD options. Now to let you guy's in on how we operate. As you guy's know it's time to change when you need other computer posts just to scan your drawings cause your new scanner isn't compatible with win98. What's annoying is that the program is getting pretty old so we cant run higher than win98.

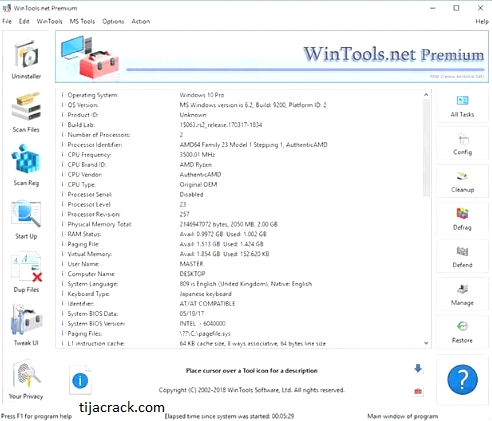

We are currently using completely unlocked CMS Wintools as the main programming software. We are in process of upgrading our programming software but have a hard time finding what suits us.

0 kommentar(er)

0 kommentar(er)